USES - Multistage vertical pumps. Pumping of clean non-loaded fluids in the domestic, agricultural and industrial sectors; pressurizing systems; irriga- tion; drinking and glycol water; water treatment; food industry; heating and air conditioning; washing system.

ADVANTAGES - Closed coupled and compact; silent; excellent efficiency that allows a reduction of running cost ad powers; economical; overdimensioned bearings for longer life of the machines; intermediate shaft guiding stage for concentricity of rotation.

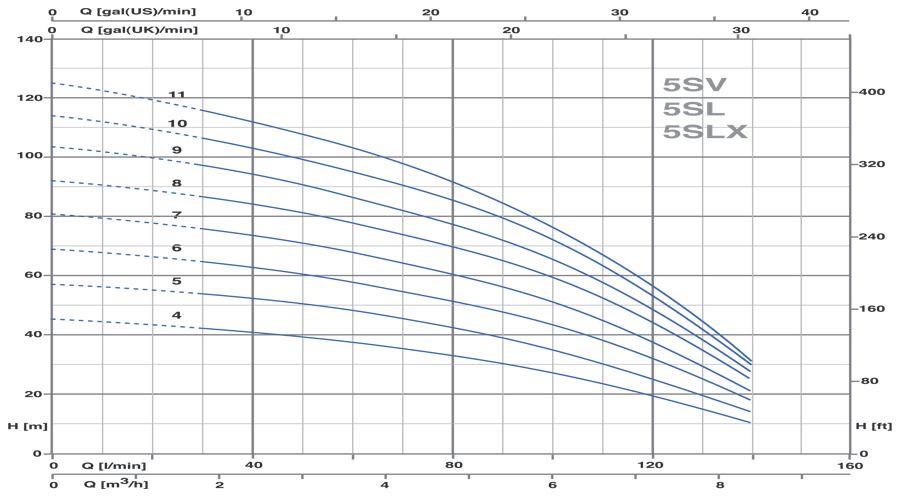

CONSTRUCTION FEATURES - Capacity: up to 26 m3/h; total Head: up to 125 m.; maximum working pressure: 8 bar ≤ 6 impellers. 14 bar > 6 impellers; maximum liquid temperature: from -15 to + 90 °C (SV); from - 15 to 110 °C (SL, SLX) ambient temperature: max 40 °C.

MOTOR - 2 pole induction Motor; single phase 230V - 50Hz with thermal protector up to P2= 1,85 kW; three phase 230-400V - 50 Hz; insulation class F; protection degree IP 44.

MATERIALS - Flanged siction and delivery pump body: grey cast iron (SV,SL) AISI 304 chromo-nickel steel (SLX);flanged delivery pump body: cast iron; shell, impellers, diffusers: AISI 304 chromo-nickel steel; pump shaft: AISI 304 cromo-nickel steel; motor bracket: cast iron; mechanical seal: ceramicgraphite up to 6 stages - graphite-silicon carbide from 7 stages; intermediate shaft guiding stage bush: ceramic-tungsten carbide; pump body gasket: EPDM.

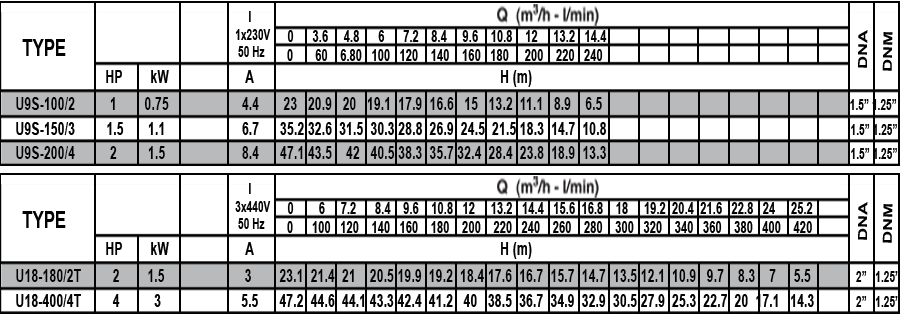

PUMP PERFORMANCE