WORKING PRINCIPLE - 4STM pumps are MULTISTAGE CENTRIFUGAL PUMPS designed for permanently immersed operation. The motor is connected to the pump by means of a support designed in accordance with IEC standards. The operating principle is that of multistage centrifugal pumps. The impellers, supported by the motor shaft, rotate inside vane diffusers which transfer the liquid leaving each impeller towards the suction opening of the next; Once the liquid has passed through the series of impellers it is expelled via the delivery opening. Each impeller and its respective vane diffuser constitutes a pumping stage which, according to the operating principle of centrifugal machines, generates a pressure increase in the fluid which is added to each subsequent pressure increase induced by the other stages in series.

PUMP INSTALLATION AND APPLICATIONS - THESE PUMPS ARE SUITABLE FOR PUMPING CLEAN WATER OR FLUIDS WITH A SAND CONTENT OF NO MORE THAN 150 g/m3. THEIR HIGH PERFORMANCE AND DEPENDABILITY MAKE THEM SUITABLE FOR USE IN DOMESTIC, CIVIL AND INDUSTRIAL FIELDS, FOR THE AUTOMATIC DISTRIBUTION OF WATER WORKING IN CONJUNCTION WITH STORAGE TANKS, FOR DOMESTIC, CIVIL, WASHING, PRESSURE-BOOSTING SYSTEMS AND FOR FIRE-FIGHTING PURPOSES, ETC. 4STM pumps can be installed in wells with a diameter of no less than 4" (100 mm). The pump is lowered Into the well by means of the delivery pipe until it is completely immersed (min. 100 cm, and at least one meter from the bottom of the well) even when working, as pump operation may obviously cause the level of the liquid in the well to fall. The pump can be installed vertically, when installed vertically in a well, it is advisable to secure the pump by using a stainless steel or nylon cable connected to the special holes provided on the discharge head.

PERFORMANCE - AC pumps combined the advantages of a submersible pump with the performance of a centrifugal pump. In fact, as submersible pumps, they assure: - reliable operation even with considerable water depth. At the same time, as multistage centrifugal pumps they assure: - outputs having high absolute values, ample and particularly stable curves. Curve tolerance according to ISO 2548.

STRUCTURAL CHARACTERISTICS -

UNI ISO 228/1.1" gas thread DISCHARGE HEAD in brass (from 0.25 discharge head, check valve and motor bracket in AISI 304 stainless steel).

Technopolymer, high-resistance CHECK VALVE enables the weight of the column of water to be dispersed without stress to the impellers and diffusers, thus ensuring long pump life.

Lexan "General Electric" technopolymer IMPELLERS.

Noryl GFN2 technopolymer DIFFUSERS. J AISI 304 stainless steel BOWL

AISI 304 stainless steel EXTERNAL SLEEVE.

AISI 304 stainless steel PUMP SHAFT.

Brass MOTOR BRACKET built to IEC dimensional standards.

AISI 316L sinterised stainless steel TRANSMISSION COUPLING. J AISI 304 stainless steel BOLTS & SCREWS.

AISI 304 stainless steel FILTER.

AISI 304 stainless steel CABLE GUARD

4" SUBMERSIBLE MOTORS: Oil filled Rewindable motor

PROTECTION: IP-44 Standard

WARRANTY - 1 YEAR (according to our general sales conditions).

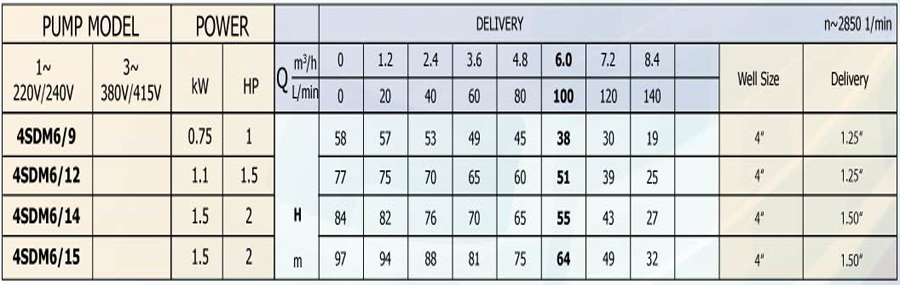

PERFORMANCE DATA AT n=2900 RPM

H= Total Dynamic Head In Meters

Q= Flow Rate